Keep It Simple. Make It Known.

Instant Material Identification. Anywhere.

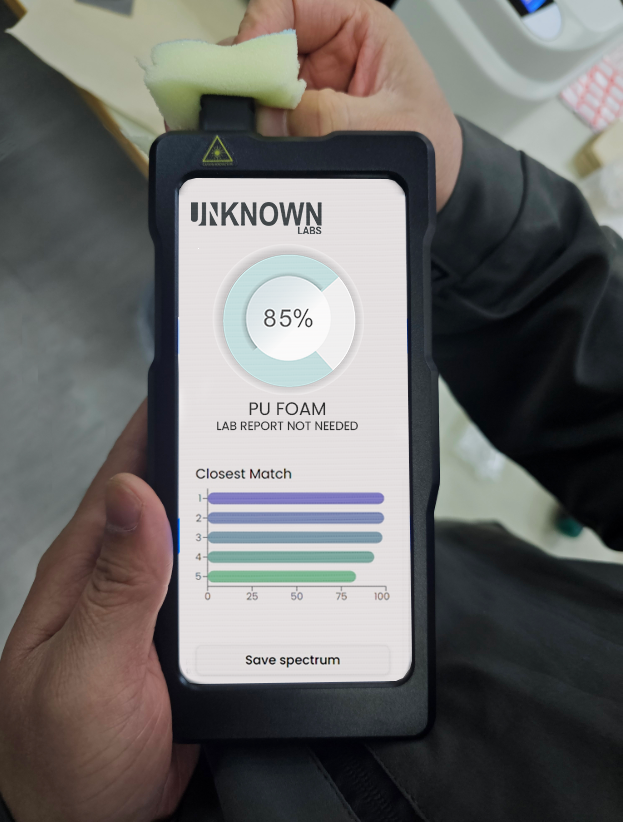

Scan a material and get a clear answer in seconds. No lab, no experts, no guesswork.

We help organizations identify materials on site, flag risks early, and feed clean data into existing workflows.

Narcotics | Environmental | Brand Protection

Don’t Estimate. Know More Than Just Your Material.

In today’s fast paced industrial environment, waiting days or weeks for lab results simply isn’t compatible with efficient, high quality operations. With our handheld/benchtop material scanning solution, teams can now identify and verify materials on the spot, in seconds, with clear “pass/fail” or “investigate further” results. All without needing specialized lab equipment or expert interpretation. This capability transforms material identification from a bottleneck into a real time decision making tool, allowing quality assurance, production, safety, and compliance teams to act immediately with confidence.

Unlike traditional sampling that requires shipping, queuing, and expert analysis, every scan you perform with our device is automatically saved into a searchable internal database, building organizational knowledge over time.

With us structured data becomes a powerful asset.

Turnkey Solutions that use us.

-

Identify plastics, composites, unknown waste

Verify sorting decisions

Reduce contamination and misclassification

Build traceability over time

-

Verify liquids, powders, materials

Detect substitutions or dilution

Compare against known references

Protect brand integrity at scale

-

Incoming material verification

Supplier checks

Process monitoring

Audit support

-

Screen unknown chemicals

Flag dangerous substances early

Decide what needs lab confirmation

Improve worker safety

-

On-site substance identification

Detect adulterants and cutting agents

Track trends over time

Support harm reduction programs

More Details of our solution.

A Universal Spectrometry Platform:

With our cloud software you can connect to and control multiple devices in real time without complex software engineers on your staff. Your Admin can instantly visualize all data, overlay multiple spectra and compare or combine them to precisely identify materials. They can also monitor, track changes and update spectrometer settings from anywhere in the world.

The same system is used in heavily secured Milipol Environments.

-

Instantly view live data streams from anywhere between 1 and 10,000 connected spectrometers worldwide.

-

Overlay spectra from different instruments or tests for comprehensive material comparison and let the AI assist in your decision-making, guided by your parameters and oversight.

-

Select specific spectral ranges. Those will be highlighted so you can identify key peaks of interest that you can reference instantly.

-

Compare a new scan against your library of similar materials to detect variances or confirm matches. Take it one step further and compare it against ALL your data to identify trends.

-

Use combined spectral data to determine material composition, treatments, or anomalies.

This platform enables streamlined decision making, remote collaboration and flexible customization all from a single, cloud connected interface.

Custom Software. Easy and Fast. Already done.

BEGINNER MODE:

Ideal for commercial exhibitions and highlighting aesthetics. Show off your brand in new ways.

-

Start a scan and get instant material suggestions.

-

Automatically compare new data with your known samples.

-

Step-by-step instructions with visual cues.

-

Technicians or labs can assist remotely in real time.

Go I No

Designed for speed and simplicity, our software is ideal for both automated pick and place systems and handheld, on the spot devices. Whether you need quick looks, fast readings, or clear go/no-go decisions, it delivers instant insights and seamless integration. Perfect for lab use, factory floors, or field operations.

Save Time, Money, and Avoid mistakes.

Field equipment that’s proven, User interfaces that are easy to read, Cloud storage infrastructure to track trends, compare batches, generate reports, export results to existing systems, and integrate material verification into your normal quality and safety workflows. Rather than one off tests, material identification becomes an ongoing, intelligent process that enhances traceability and accountability across your operation.

By embedding rapid material verification directly into your workflow, your teams can reduce costly delays, avoid production errors, and drastically cut dependency on external laboratories. Our solution ensures materials are right before they move forward.

Whether it’s incoming inspections at a warehouse, raw material checks on the factory floor, or safety screening in field conditions. Fast, reliable, and actionable results empower your teams to make confident decisions on site, maintain compliance, and boost operational efficiency, ultimately saving time and money while improving quality and safety outcomes.

NEED A DEMO?

Talk to an Expert. We are here to help.

We turn complex material analysis into a simple scan and answer experience.

Scan a material on site.

Get an instant result.

No scientific background required.